TECHNOLOGY

We endeavor to develop core technologies of digital electric / electronic control and to develop quality products based on high reliability.

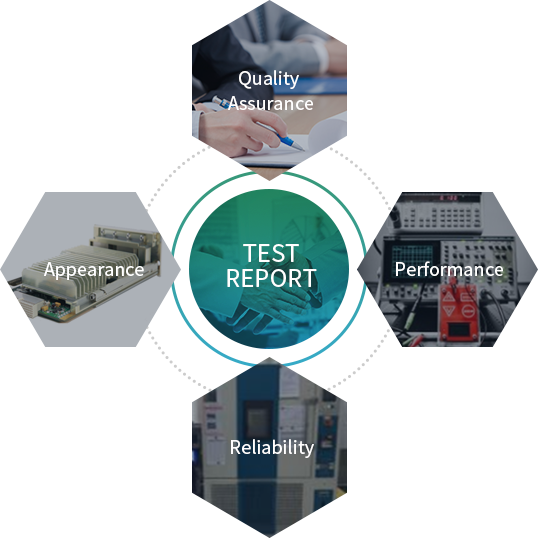

Quality Assurance

Based on the highest level of human competence and high-reliability quality-based manufacturing capability, we have a complete quality assurance system, from material incoming to complete product outgoing through continuous quality innovation activities In addition, we have acquired ISO-9001: 2015 and AS 9100 certification through the establishment of a successful quality management system.

- * Ensuring quality and traceability of incoming product : Checking quality related documents like COC, test reports

- * Performing quality inspection according to import inspection procedure and standard: Test report - Perform forged parts inspection to secure part reliability

Ensuring quality reliability and traceability of incoming materials

- * Carrying out visual inspection for soldering/coating/molding by IPC international standard function certification holder

Close Inspection per Process Unit

-

Full inspection for soldering by X7 ~ x45 magnification microscope

Full inspection for soldering by X7 ~ x45 magnification microscope

-

Full-coating / molding inspection through X5 magnification UV lamp magnifier

Full-coating / molding inspection through X5 magnification UV lamp magnifier

- * Performing a completion inspection on the module level finished products

- * Completion inspection using electrical performance tester, S / W application test and automatic inspection equipments

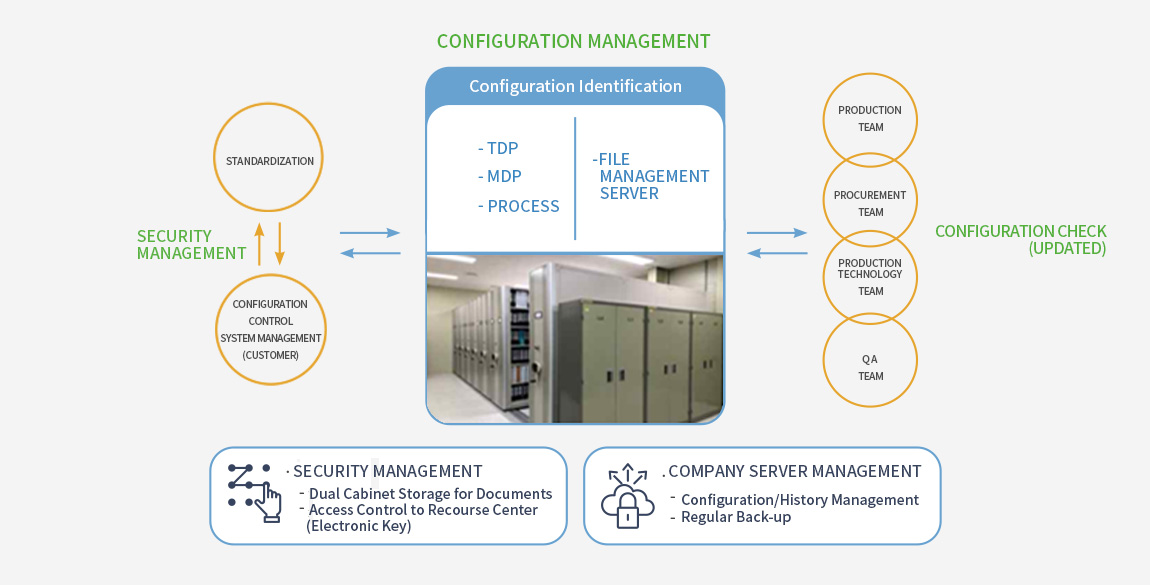

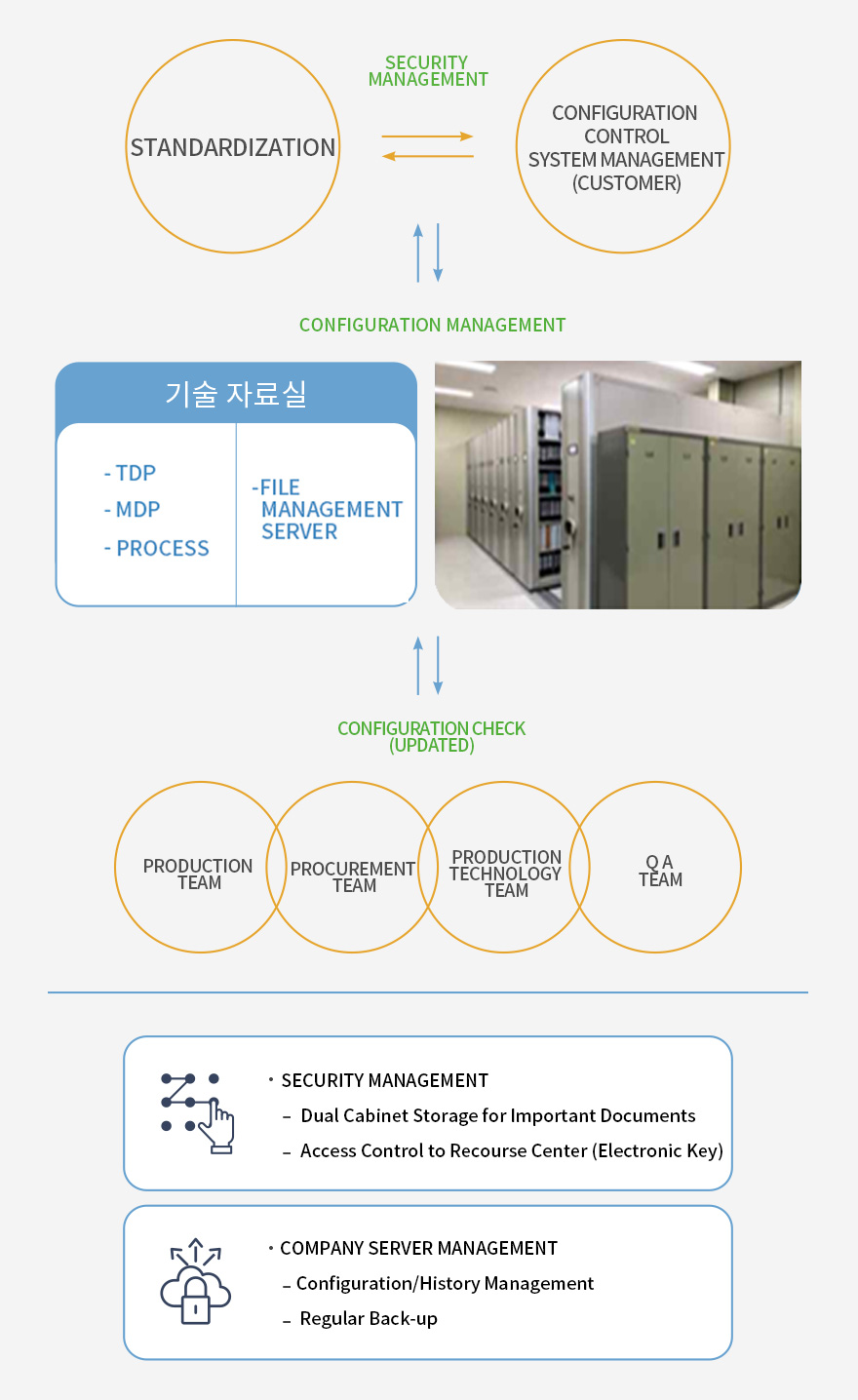

- * Documentation to identify the functional or physical characteristics of the strategic items

- * Checking on conformity in between products and the change control and configuration identification (drawings, specifications, etc.)

- * Record / maintain necessary information such as the status of implementation of approved shape change

Configuration Management