TECHNOLOGY

We endeavor to develop core technologies of digital electric / electronic control and to develop quality products based on high reliability.

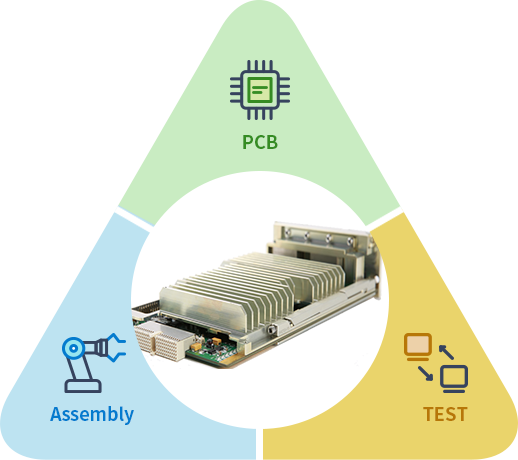

Process technology

We provide the best quality and the best delivery time based on the highest professional production facilities and the production process unit operated by the professional manpower with the national institution certification.

- * Automatic production line construction for precision parts

- * IPC-A-610 standard BGA and high direct part mass production reliability management

- * Clean room-based constant temperature and humidity control for production of high quality products

- * Applying N2, ensuring product life-span

- * Construction and operation of SPI AOI / X Ray equipment for quality inspection and analysis by process unit

- * Acquisition and application of special process certification

SMT line and Clean Room configuration for quality product production

-

Cleanness Management

- 50,000 ClassEnvironmental Maintenance

- Temperature : 23℃±5 - Humidity : 40 ~ 60%Rh -

Illuminance

- Over 1,000 LuxCirculation

- Positive pressure air-conditioning system

Automatic Production for Precision Parts

Chip Size : 1005 (mm)

BGA Parts (Ball Size: 0.4mm, Pitch: 0.65mm, N2 REFLOW to improve reliability)

-

Loader

-

Screen Printer

-

SPI

-

MOUNTERI, II

-

REFLOW(N2)

-

UN-Loader

-

AOI

-

X-ray

- * Wire harness and electronic assembly and inspection by IPC international certificate holders

- * Precision manual operation of x7 - x45 magnification

- * Rework certification and facility construction for BGA / LGA defects

Performing the soldering work process and inspection by IPC international standard function certification holder

-

IPC-A-610

Application Specialist Training

Acceptability of Electronic Assemblies

-

IPC-WHMA-A-620

Requirements and Acceptance for Cable

and Wire Harness Assemblies -

IPC-7711/7721

Rework and Repair of Electronic Assemblies

-

IPC-J-STD-001

Requirements for Soldered Electrical and Electronic Assemblies

- * Complete assembly line for module level and setting up a dedicated test line

- * Operating performance test using electrical performance test, S / W application test and automatic inspection equipment

Test software application and electrical performance test for each product

- * Applying MIL-STD 810 Standard - Environmental Stress Screening - Temperature & Humidity Tester - Thermal Shock Tester

Reliability Testers

-

Temperature & Humidity Tester

Temperature Operation Range : - 40℃ ~ 85℃

emperature Change Rate : 2℃/min, 3℃/min, 5℃/min

Humidity Operation Range : 30℃ ~ 60℃ to 95%±4% -

Environmental Stress Screening

-

Thermal Shock Tester

Temperature Operation Range : - 60℃ ~ 180℃

Temperature Change Rate : ΔT1 - ΔT2/min